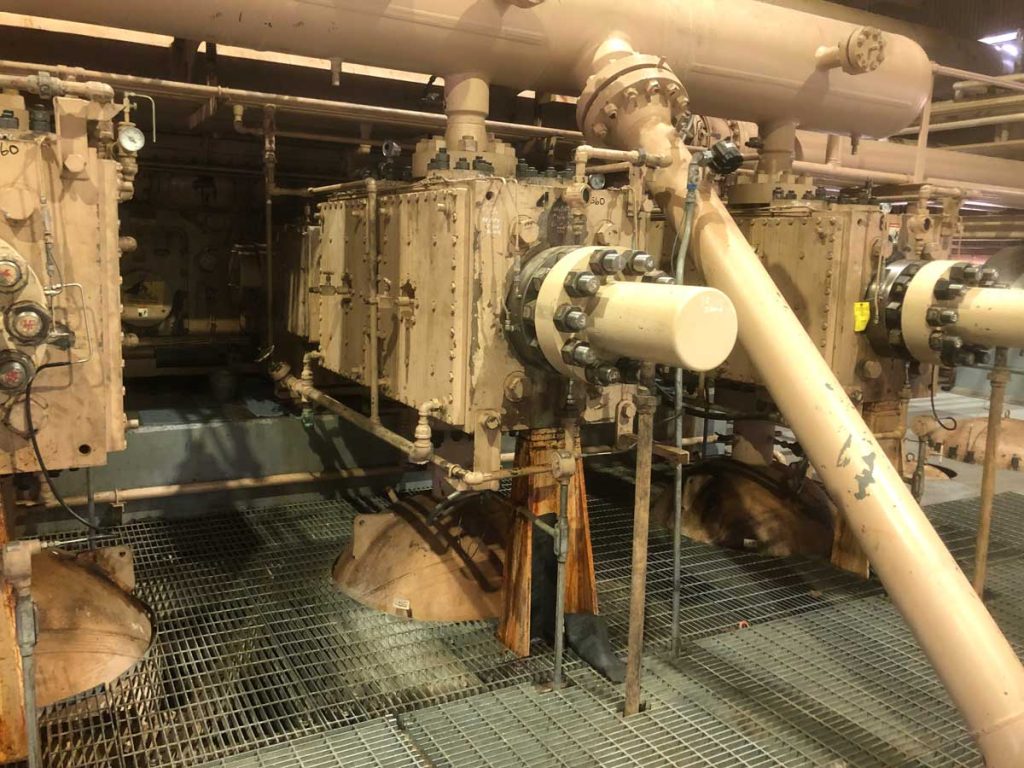

Have you ever seen a unit wagging its tail? A tail shaft could be used to hook multiple compressors together, but why have one on a unit like this? Manufacturers use them to create rod reversal which lubricates the crosshead pin and bushing. Under certain speed and pressure conditions, a crosshead pin and bushing can fail to cycle and burn up. One of the main contributors to this is the difference in crank end versus head end pressure created by the smaller piston face surface area of the crank end due to the rod connection. An easy way to engineer that out? Put a tail rod in the head end side of the piston. That will even out the pressure and allow the pin and bushing to receive proper lubrication and live a long and happy life together. Join us at the Eastern Gas Compression Roundtable on May 3-5, 2022 at the David Lawrence Convention Center in Pittsburgh.

Have a tip? Do you have a technical tip to share? Submit your tip, along with an associated image and we may include it in our Technical Tuesday social media posts, blog posts and emails.